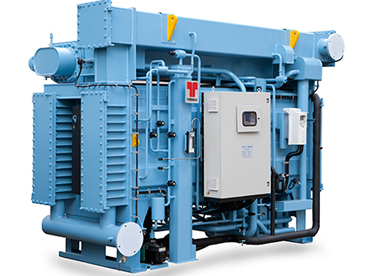

VAM – Vacuum Absorption Chillers

Absorption chillers use heat to drive the refrigeration cycle, they produce chilled water while consuming just a small amount of electricity to run the pumps on the unit. Absorption chillers generally use steam or hot water to drive the lithium bromide refrigeration cycle but can also use other heat sources.

Absorption technology reduces the requirement for electric energy and can give owners flexibility where electrical demand and consumption are expensive or in short supply.

It is not only reduces greatly the cost for electricity and operation fees in regions where there are rich steam resources, but also compensates the peak-valley load difference. When the hot summer rolls in, shortage of electric power will poses a great worry for various cities.

These absorption chillers are widely applied in industries, such as precision machinery manufacturing, instruments & meters, aviation & aerospace, textiles, electronics, electric power, metallurgy, pharmaceuticals, cigarettes, chemicals, hospitals, food, etc.